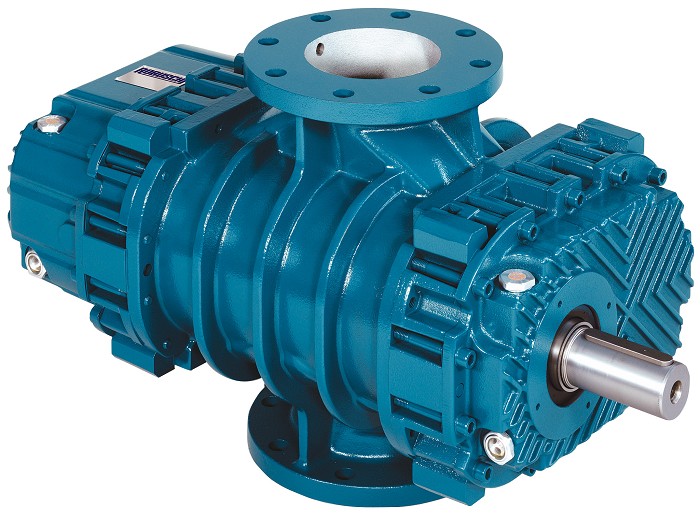

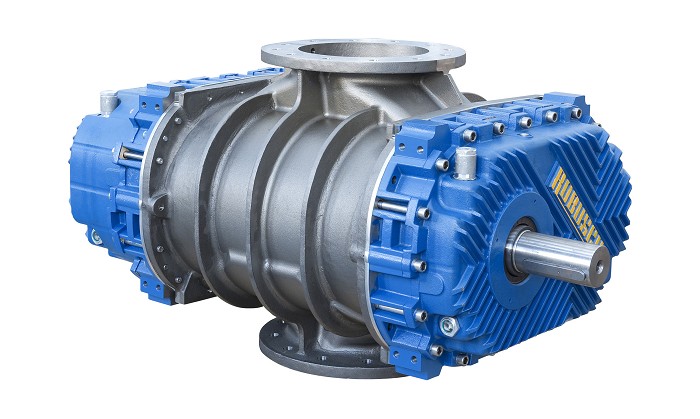

The RBS series devices are positive displacement blowers consisting of two rotors coupled by a precision synchronous

gearing, which rotate counter-rotating inside the compression chamber at a speed of up to 5000 rpm. The structure is

completed with oil chambers separated from the gas part by a system of labyrinth seals. The precisely made cast iron

housing guarantees very good product durability.

The gas enters the blower at pressure P1 and temperature T1, then it is transported in the space between the rotors of

volume V and discharged under pressure P2 and temperature T2. Efficiency is proportional to rotational speed and varies

with changes in operating pressure.

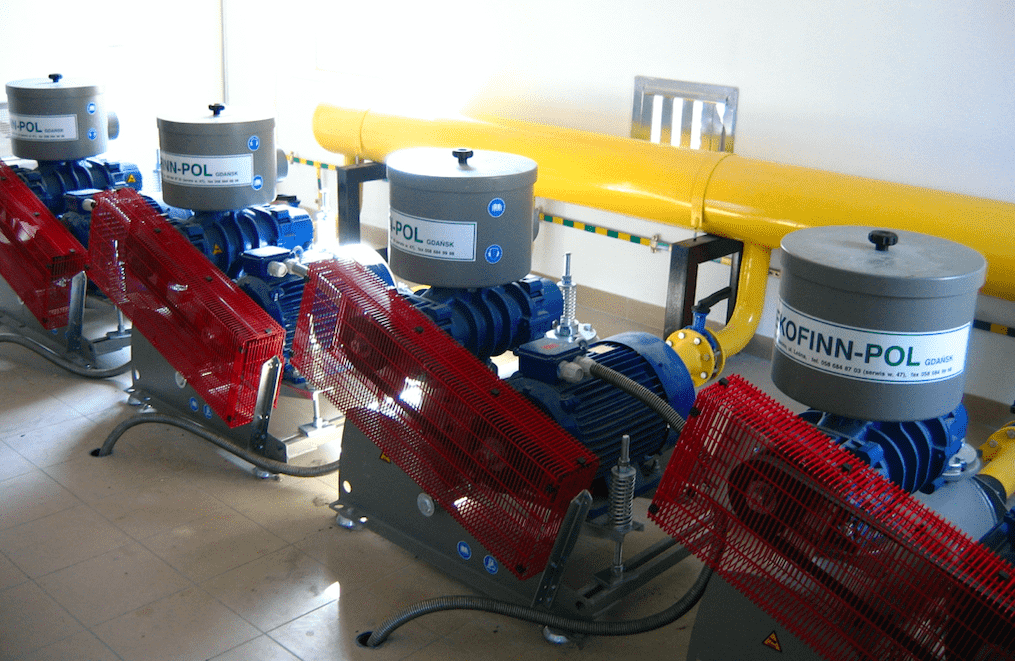

The RBS series bare shaft blowers are the main design element of the ROBOX LOBE (formerly ROBOX evolution) blower. Their

service requirement comes down to monitoring the oil level in the oil sumps. The Robuschi blower efficiently forcing air

and / or gases is used in everyday operation, in sewage treatment plants, water treatment plants, pneumatic transport or

other industrial installations.

RBS bare shaft blowers are known for their very good user feedback. With proper servicing, it is not uncommon for

original RBS units exceed twenty years.

After it has been worn out, a general overhaul of the entire component is possible. Such general overhauls and service

can be ordered in our company. Due to over 20 years of experience and quick access to original components, it is worth

ordering and servicing them only from an authorized Robuschi distributor.

We have RBS units on-site in stock, so we can provide short shipping times that go hand in hand with favorable prices.

Rapid delivery times make them equally eagerly used by users of blower skids from other manufacturers, for whom the

continuity of their installations is of key importance.

RBS bare shaft blowers can come in several variants, each of which can be additionally adapted to work in a potentially

explosive atmosphere (ATEX):

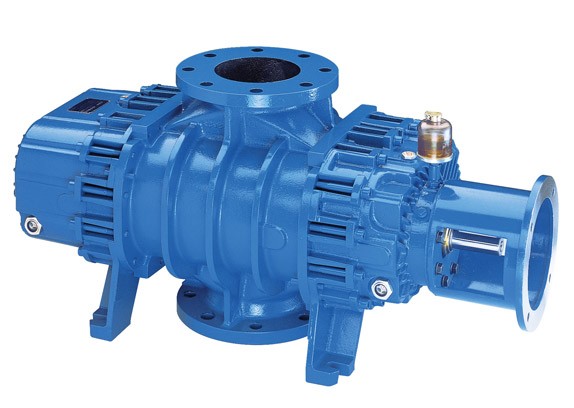

- stainless steel version, RBS-STEAM

All blower components that come into contact with the conveyed gas are made of stainless steel (AISI 316 or DUPLEX),

therefore they are corrosion resistant and suitable for the toughest operating conditions such as evaporation processes

and wastewater treatment. Various configurations are available with a variety of sealing systems such as lip and

mechanical seals and a combination of materials (stainless steel and cast iron), allowing the customer to choose the

most appropriate solution depending on the chemical composition and type of system. To facilitate maintenance, on the

PRV version, specially designed side plates allow immediate access to the sealing system.

- version with a special coating and dedicated shaft seals

Two types of coatings are available for those parts of the blower that come into contact with aggressive liquids

(housing, sides and impellers):

- Niploy (electroless nickel plating): guarantees high resistance to corrosion and wear.

- Chemcoat (fluoropolymer cladding): guarantees corrosion resistance in contact with moist substances, has anti-adhesive

and sliding properties.

Available for models RBS 15 to RBS 225

The blower is equipped with two cooling coils which keep the oil temperature below 100 ° C regardless of the operating

conditions. This version is recommended when the outlet gas temperature exceeds 140 ° C.

Available for models RBS 75 to RBS 225, only in vertical (/ V) version.

Special versions:

- ATEX

- oil cooling in oil sumpss

- special inner coatings

- INOX (AISI316 / DUPLEX)