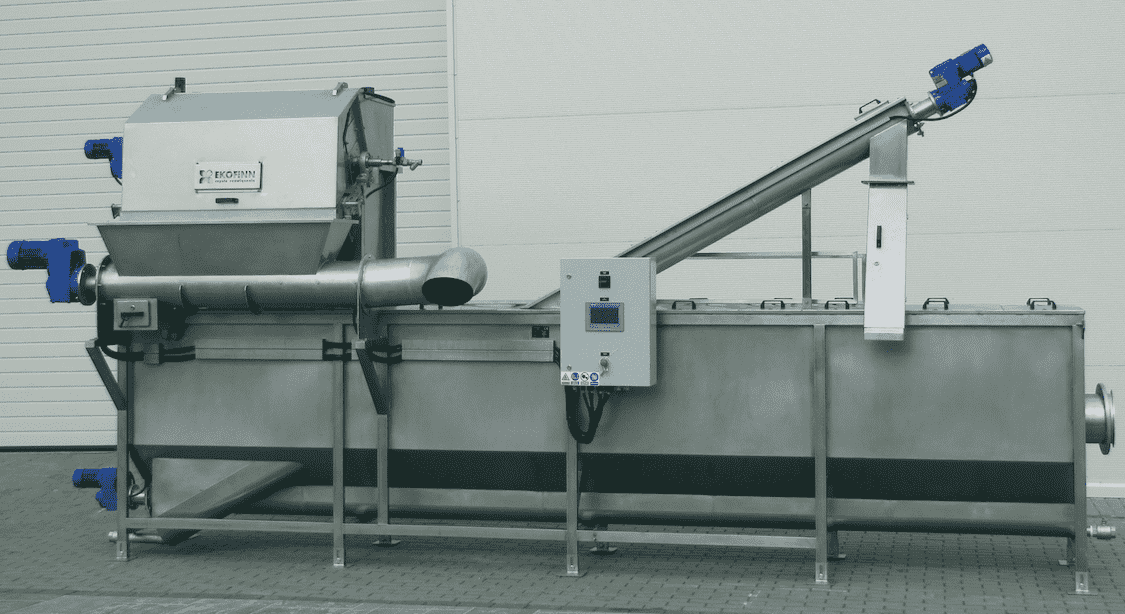

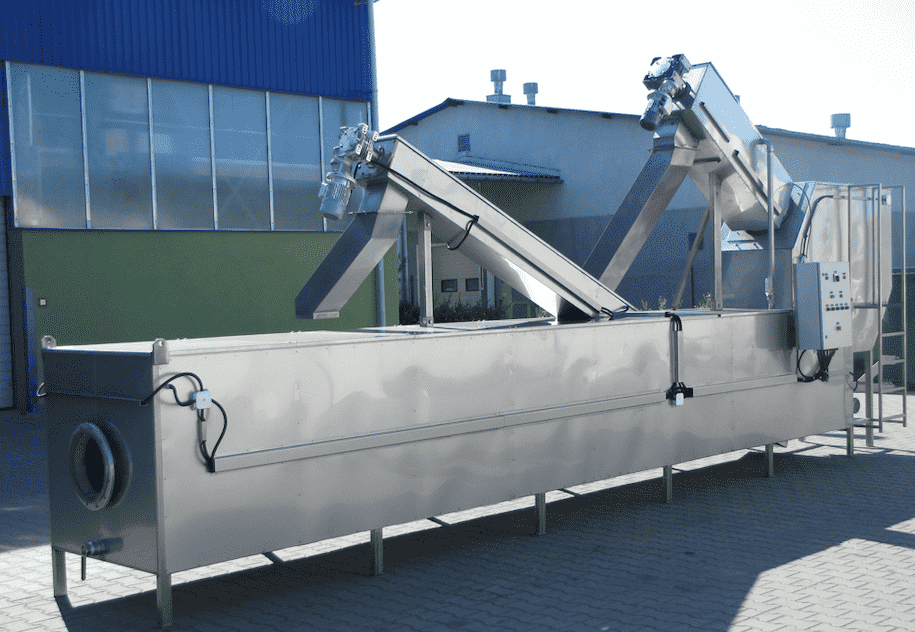

The Screening and Grit Separator allows you to combine both stages, at the same time separating the screenings and settling mineral sediments. Compact devices with a throughput of 5 to 100 m3 / s with an integrated screen part are an excellent alternative to traditional screens and separate sand traps that require more space and additional maintenance.

The Screening and Grit Separator incorporated into the technological line of the sewage treatment plant improves the

entire process while maintaining the appropriate throughput. The offer includes solutions using both spiral and drum

screens.

The principle of operation of a Screening and Grit Separator with spiral and drum screens is the same. Sewage from the

sewage system flows into the inlet chamber, which is also responsible for the retention of peak liquid flows. In the

event of a power cut, this point also acts as an emergency overflow. In the case of a spiral screen, a cylindrical

strainer separates the pre-solids and prepares them for transport. It takes place with the help of a worm ribbon, which

carries the load of the screenings up to the chute, where they are subject to dewatering. In the case of a drum screen,

the screenings, after being separated on a screen, are usually fed to the screenings press in order to dehydrate and

thicken them. When leaving the screening zone, in the case of both types of sieve, the sewage without screenings flows

to the second part of the installation - a horizontal sand trap, in which, due to partial settling due to gravity,

sedimentation is carried out, i.e. the deposition of heavier mineral particles at the bottom of the tank. From here, the

sand is transported by screw conveyors to a separate discharge for further storage, optionally preceded by washing. For

most applications, spiral screens for the mechanical separation of waste and solids from raw sewage will perform

excellently. In the case of some industrial wastewater or wastewater with a large amount of fibrous pollution, such as

rags, strings, foils, a Screening and Grit Separator with a drum screen will certainly be a more effective solution. The

device is used indoors and outdoors with thermal and heating insulation.

In the treatment process, one of the most important parameters is the amount of wastewater that can be treated in a

specific time unit. The offered series of Screening and Grit Separator types with a capacity of 5 to 100 liters per

second will be perfect for a wide range of flows in sewage treatment plants, both municipal and industrial. The use of

very ergonomic technologies does not generate high costs - purchase, assembly and further operational costs are within

the limits of economic calculation. The compact size of the device, in which the horizontal sand trap and oblique spiral

screen or small drum screen do not take up much space, also reduces the space necessary to set up the entire technology.