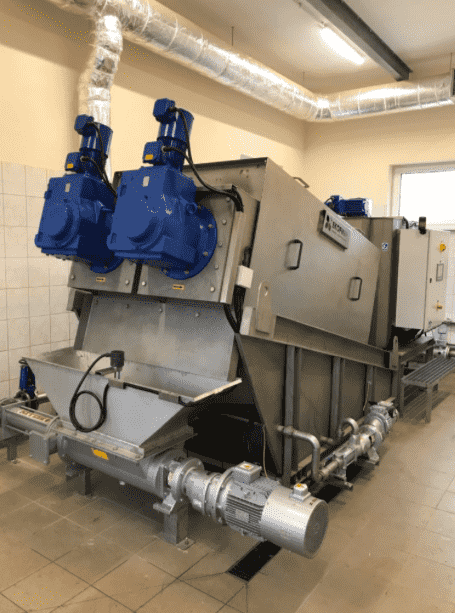

The multi-disc screw presses are perfect for the dewatering of municipal and industrial sludge. We offer these devices

in single, double and triple screw versions, with a diameter of 250 to 400 millimeters and a throughput of up to 20 m3 /

h. The devices are delivered as a package with an automatic polyelectrolyte station and a dynamic flocculator.

The main advantage of the multi-disc screw press is affordable operating costs related to low energy consumption, low

consumption of reagents and practically negligible water demand. The device is also recommended for dewatering sludge,

which contains a high dry matter content, so they can also be used in industry. An additional advantage of the product

is the structure itself - closed and compact, occupying a small area.

These presses also achieve very good dewatering results, comparable to belt presses. The final results depend on the

type of sludge, its degree of mineralization and stabilization. With the help of the device, you can get from twelve to

more than twenty percent of dry solids concentration. It is worth mentioning here that satisfactory results are achieved

both in the case of small and larger sewage treatment plants. Contrary to centrifuges and belt presses, the device is

suitable for the treatment of sludge containing oily substances, including fats.

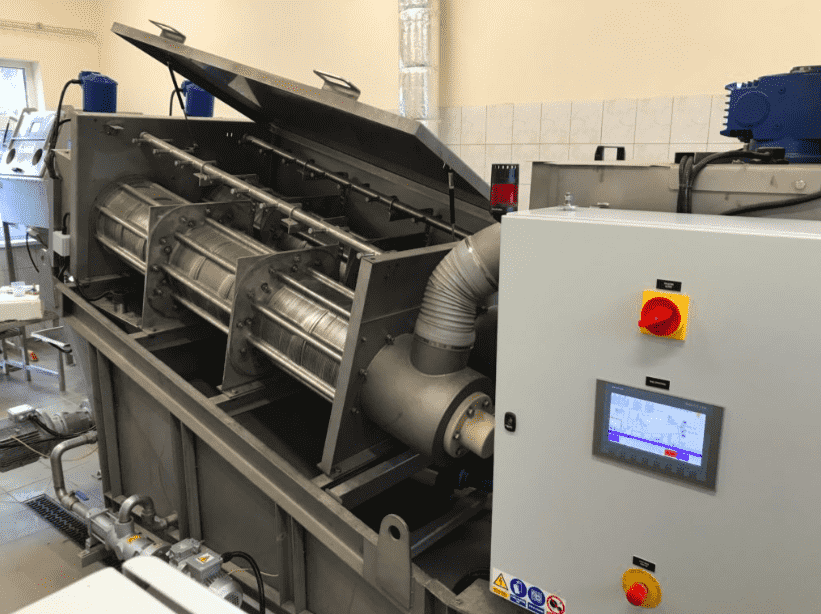

The principle of operation of the device differs from typical dewatering solutions used in sewage treatment plants, such

as chamber presses, belt presses or decanter centrifuges. The device consists of two basic elements combined into one

unit: a two-chamber dynamic flocculator and a multi-disc screw press.

The sludge, previously mixed with polyelectrolyte in a flocculator with adjustable speed of stirrer, enters the press,

where it is subjected to gradual compression by slowly moving it through a screw with a decreasing pitch and increasing

diameter of the core. The screw moves the sludge inside the moving rings (discs), where the water flows from the sludge

being dewatered, causing it to thicken and dewater under the influence of the shrinking space. Additionally, the

discharge of the sludge from the press is equipped with a disk with adjustable pressure force, allowing the possibility

of setting the desired degree of sludge dewatering. As an option, the device can also function as a sludge thickener

with a significantly reduced compaction pressure.

In the initial stage of dewatering, the filtrate is clean and does not require further treatment before it is discharged

into the sanitary sewage system. At the end of the device, due to the intense squeezing of the sludge, the filtrate

usually contains a larger amount of suspended solids. Therefore the PST screw press, where necessary, is equipped with a

separate dirty filtrate chamber and a circulation pump returning this filtrate to the beginning of the dewatering

system. Thanks to this solution, the filtrate reaching the outflow is characterized by a small amount of suspended

solids.

The use of movable discs, between which the water flows, allows for self-cleaning. The sludge dewatering process itself

on the PST screw press does not require constant washing water consumption.

The press housing and discs are made of AISI 304 (1.4301) steel as standard. In order to protect the screw against

abrasion, it is hardened with tungsten carbide to a value> 70 HRC.

The press control panel provides automatic operation, during which the following functions are performed: control of the

screw rotation speed, the flocculator stirrer, periodic flushing of the outer surface of the rings, feeding of the

sludge and polyelectrolyte (when the press cooperates with the polymer dosing station).