Professional granulation allows the sewage waste to be physically formed into stable granules of a certain size. As a

result, their further storage and transport are much simpler and safer. Above all, however, the processed sludge can be

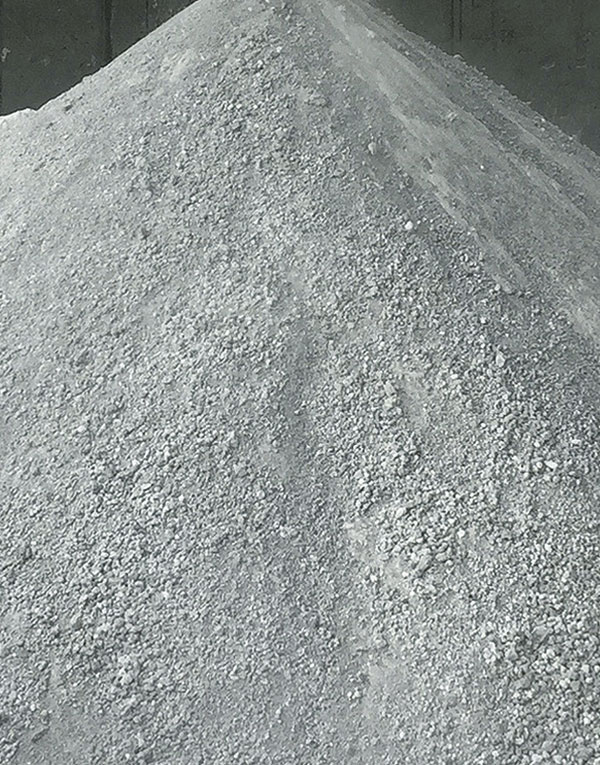

utilized, which is important from the point of view of environmental protection. The product (granulate) in the

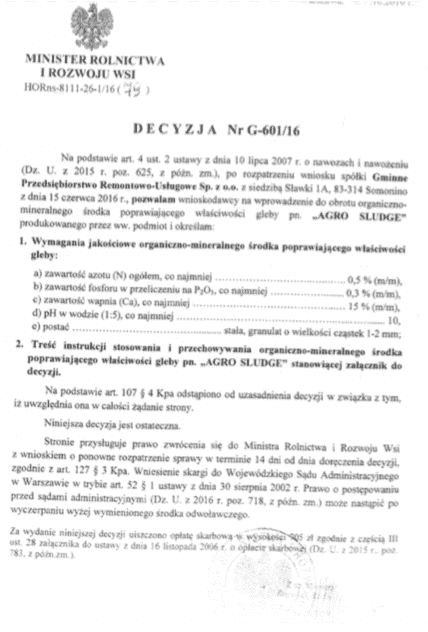

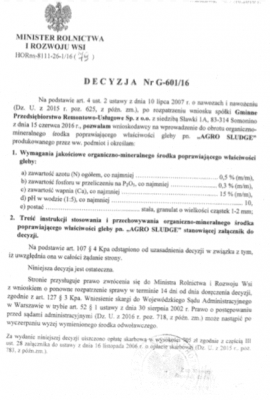

granulation process, after obtaining the permission of the Ministry of Agriculture, can be marketed and used as a soil

improver.

In the Wilk sludge granulator, a high degree of sewage sludge hygienisation also takes place during the granulation

process. It is a very important element of the technological process, enabling full sludge stabilization. The sludge is

carefully mixed with highly reactive quicklime, which chemically stabilizes and removes pathogenic bacteria, parasites

and their spores. The sludge granulation process, enabling a high degree of hygienisation, is highly recommended for

ecological reasons.

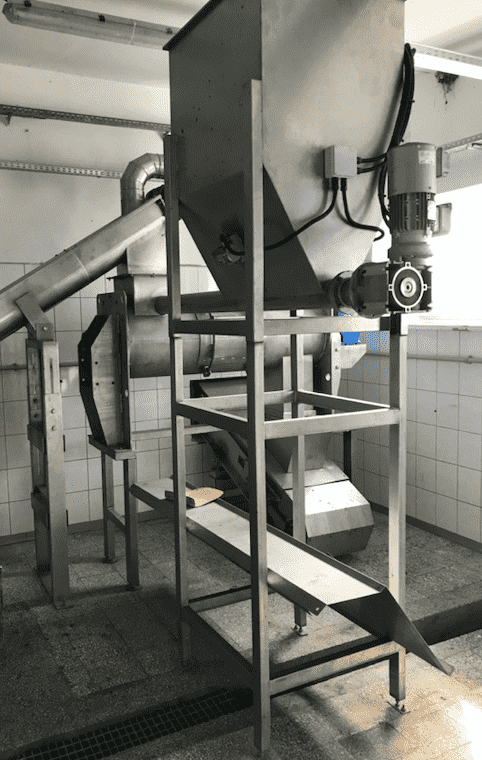

The granulation process is illustrated in the video on our website. With the help of this equipment, you can create a

complete line for the hygienisation process and sludge granulation. The equipment, apart from the reactor itself,

includes silos for storing lime, as well as sludge and granulate conveyors together with a precise lime dispenser.

Individual components will be connected to each other forming one system, which is controlled via a touch control panel.

The sludge from wastewater treatment is first thickened and dewatered. The thickened sludge is transported by a screw

conveyor to the reactor. On the other hand, a precisely defined dose of highly reactive quicklime is dosed into the

reactor. The device uses a modern mixing system, which includes a rotating shaft ending with plowshares transporting the

material through successive chambers. Inside the reactor, both components are thoroughly mixed with each other, where

the reaction of hydrating the lime with water contained in the sludge takes place. During the reaction, a high

temperature (up to 100˚C) is generated, resulting in the production of a stable product with a granular structure.

Granulated and stabilized sewage sludge is mainly used for the fertilization of agricultural crops. Granules are an

excellent soil improver, increasing soil fertility. Recommended especially for acidic soils. It can be used in areas

where agricultural crops are grown for trade, as well as for compost or forage. In addition, the granules can be used in

horticulture, grassland, forestry, land reclamation and the cultivation of ornamental plants.